The Essential Role of Shoe Last in Crafting the Perfect Pair of Shoes

When it comes to shoes, the beauty and functionality we enjoy on our feet are the result of a meticulous and intricate process. At the heart of this process lies a critical element known as the “shoe last.” This unassuming piece of the puzzle plays a central role in shaping, designing, and creating the diverse range of footwear we see and wear today. In this comprehensive exploration, we will delve into the multifaceted world of shoe lasts, uncovering their historical significance, their impact on shoe design, and their vital role in the modern footwear manufacturing industry.

The Genesis of Shoe Lasts

To understand the importance of shoe lasts, we must first look back in time. The concept of a last has been woven into the tapestry of human history for centuries. The term “last” finds its etymological roots in the Old English word “laest,” which intriguingly translates to “footprint.” This historical connection between the word and its function underscores the fundamental role a shoe last plays in shaping a shoe to mimic the contours and shape of the human foot.

Remarkably, shoe lasts have been traced back to as early as the Greek and Roman civilizations, dating as far back as 400 BCE. These ancient cultures recognized the significance of replicating the human foot’s form when creating functional and comfortable footwear. Thus, shoe lasts have a rich and storied history that spans millennia.

The Versatility of Shoe Lasts

One of the remarkable aspects of shoe lasts is their adaptability. They come in various materials, each offering distinct advantages. Traditionally, lasts were crafted from carved wood, allowing artisans to sculpt and shape the wooden forms with precision. This woodwork, while time-consuming, provided an unmatched level of customization.

In more recent times, molded plastic has become a popular material for shoe lasts, particularly in mass production. Plastic lasts offer consistency, durability, and cost-effectiveness. They allow for the creation of numerous shoe pairs with the same dimensions, ensuring that each shoe is nearly identical in fit and form.

Furthermore, shoe lasts can also be crafted from cast aluminum or 3D printed plastic, reflecting advancements in manufacturing techniques. These materials offer modern shoemakers a broader spectrum of possibilities in terms of design and precision.

Shaping the Shoe: The Influence of Shoe Lasts on Design

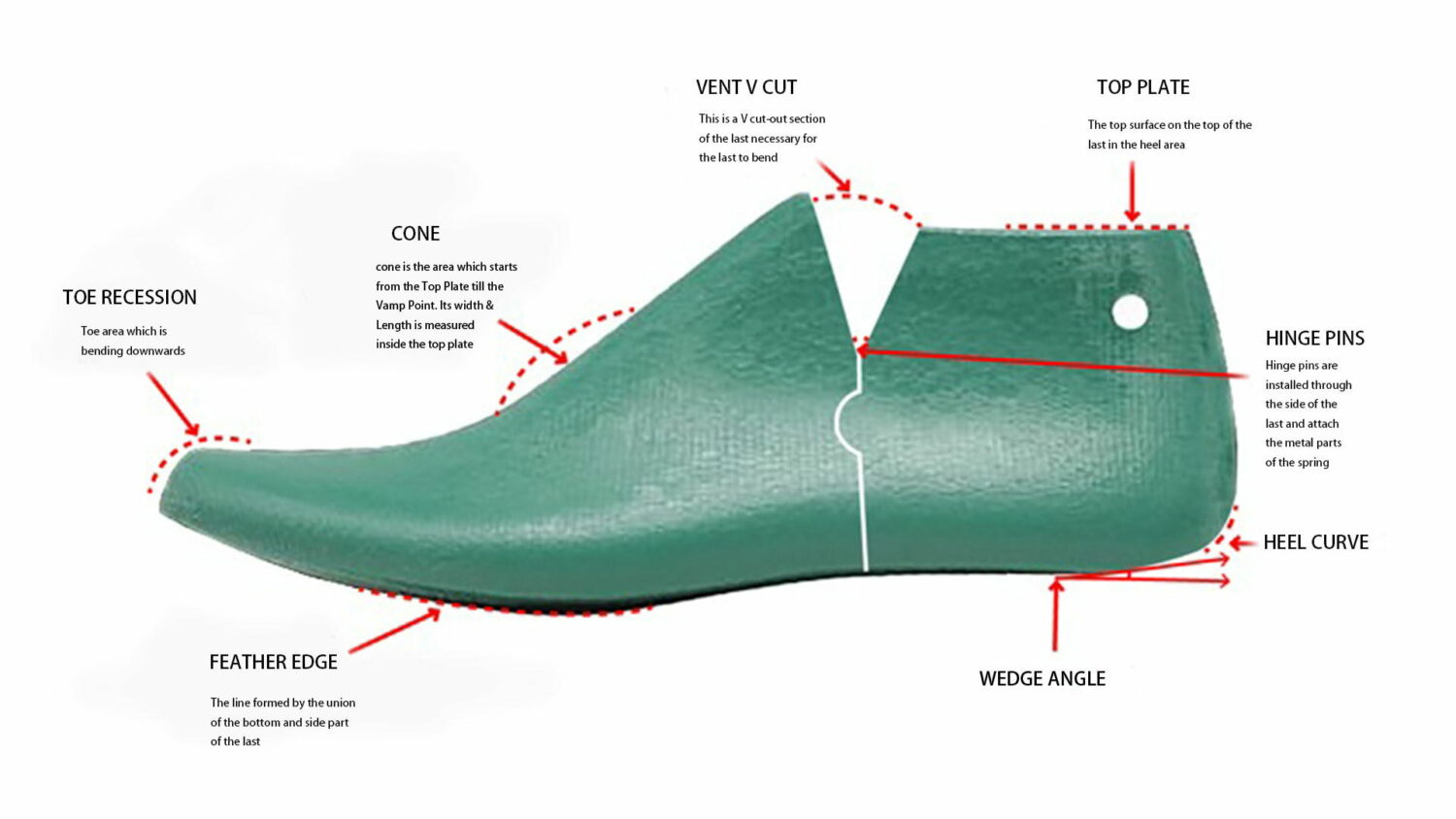

Shoe lasts are not mere static molds; they are dynamic tools that guide the entire shoemaking process. They set the stage for a shoe’s size, shape, silhouette, and comfort level. The choice of a last is paramount, as it determines the ultimate fit, performance, and style of the shoe.

During the design phase of creating a shoe, designers often work directly on the surface of a last or employ its 2D silhouette as a template for sketching their ideas. This methodology ensures that the design aligns seamlessly with the last’s shape, guaranteeing a harmonious and visually appealing final product.

It is crucial to emphasize that a shoe last is not an exact replica of the human foot. Rather, it serves as a generalized representation, accounting for the natural articulation and volumetric changes that occur as the foot moves and flexes. This understanding is particularly vital in the development of specialized footwear. Athletic shoes, for instance, undergo a meticulous design process that takes into account the biomechanics of the foot. Prominent shoe brands often collaborate with experts such as shoemakers, podiatrists, and kinesiologists to craft ideal last shapes that cater to specific activities and provide optimal support and comfort.

The Shoe Last in Shoemaking: A Journey from Concept to Production

The role of the shoe last extends across the entire shoemaking journey, from initial concept to final production. At the heart of the process, it stands as the foundation upon which each shoe is built. Here’s a closer look at the various stages of shoemaking where the last plays an indispensable role:

1.Design Phase: As previously mentioned, the design phase begins with sketches and concepts that are closely aligned with the last’s shape. The last serves as a guide for designers, ensuring that the shoe’s visual aesthetics are compatible with its intended function.

2.Development: Once the design is finalized, the shoe’s upper (the part covering the foot) is crafted and fitted directly onto the last. This step provides a three-dimensional structure that represents the actual size and shape of the shoe.

3.Production: As the shoemaking process advances, the last continues to play a crucial role. It is used to hold the shoe’s upper tightly in place, allowing for the precise attachment of the sole. The last’s presence ensures that the shoe retains its form during the critical bonding of upper and sole.

4.Quality Assurance: Beyond production, shoe lasts remain valuable tools in quality control. They help in assessing the consistency and accuracy of the final product. Shoemakers can compare the shoe’s fit and form against the last to identify any deviations from the intended design.

5.Customization: For bespoke or custom-made shoes, the role of the last is even more pronounced. Craftsmen use the last to create shoes tailored to an individual’s unique foot shape, providing unparalleled comfort and a personalized fit.

The Diverse World of Shoe Lasts

Shoe lasts come in various shapes and sizes to accommodate the wide array of shoe types available in today’s market. Each shoe type demands a specific type of last to ensure the best fit, function, and appearance. Let’s explore some common types of lasts and their significance:

1.Sneaker Shoe Last: Designed to provide comfort and support for runners, the sneaker shoe last features a sleek and streamlined shape, catering to the biomechanics of running. It prioritizes cushioning and flexibility, making it ideal for athletic pursuits.

2.Boot Shoe Last: Boot lasts have a higher ankle than shoe lasts, to provide support and protection for the ankle joint. And boot lasts are also typically more generous in fitting than shoe lasts, to allow for thicker socks and to accommodate the additional volume of the boot upper.

3.High Heel Shoe Last: High heels demand a specialized last to achieve the iconic silhouette and balance required for elevated footwear. The last for high heels accounts for the unique arch and incline of the foot.

4.Ballet Shoe Last: For ballet shoes, the last must accommodate the dancer’s pointed toe, offering flexibility and support. These lasts are designed with precision to cater to the delicate movements of ballet.

5.Materials Matter: Depending on the type of shoe construction, different materials are used for lasts. Plastic lasts are common for mass production in shoe factory, while wooden lasts are favored for custom and artisanal shoemaking. Metal lasts are employed for specialized processes like vulcanization.

Suggested articles: 8 Tips to Quickly Identify a Good Shoe Supplier