Footwear manufacturing is the process of designing, producing, and distributing shoes and other footwear products. The footwear industry is vast and complex, with many players involved, from designers and manufacturers to retailers and consumers.

There are many different ways to manufacture footwear, and the specific process used can vary depending on the shoe type, the materials used, and the available equipment and facilities.

For example, athletic shoes may be made from synthetic materials like mesh and rubber. In contrast, dress shoes may be made from leather or suede.

The manufacturing process can also vary depending on the type of footwear being produced, as well as the specific needs and preferences of the consumer.

Here is a general overview of the steps involved in the footwear manufacturing process:

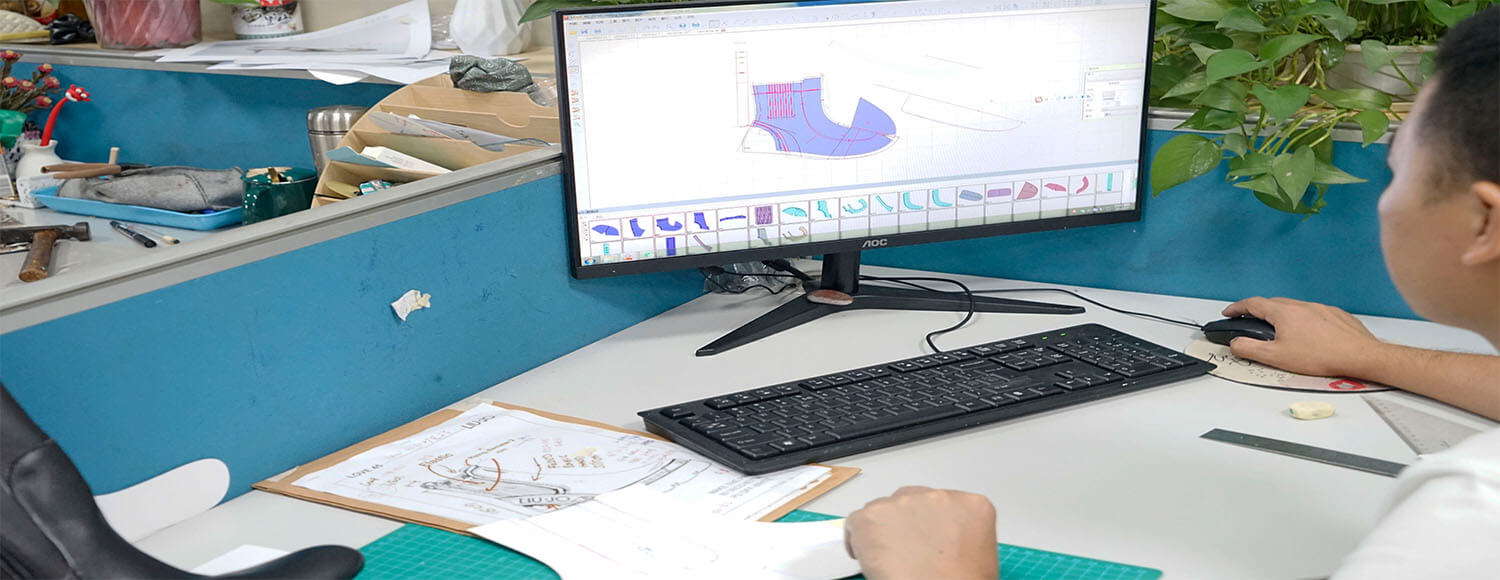

1. Design and development: The first step in the manufacturing process is the design and development of the footwear. This can involve creating a prototype or sample of the shoe, determining the materials and components that will be needed, and creating a production plan.

The designers create prototypes and drawings of the footwear products they envision. These designs are then turned over to pattern makers, who create precise templates or “patterns” that will be used to cut and shape the materials used in the production process.

2. Cutting: The next step is to cut the various components of the shoe from raw materials such as leather, fabric, or synthetic materials. This is typically done using a cutting machine or die.

Once the patterns are complete, the materials are cut and shaped according to the shoe pattern, using various techniques such as die cutting, laser cutting, or hand cutting. The materials are then sewn or glued together to form the basic structure of the footwear.

3. Stitching: Once the components have been cut, they are stitched together using a sewing machine. The stitching process can be done by hand or machine, and the specific technique used will depend on the shoe type.

4. Assembling: After the components have been stitched together, they are assembled to form the finished shoe. This can involve attaching the sole to the upper, attaching any hardware such as laces or buckles, and adding any additional features or decorations.

5. Finishing: The final step in the manufacturing process is finishing, which involves completing any final touches on the shoe, such as adding a lining, attaching an insole, or applying a finish to the upper.

6. Quality control: Before the shoes are shipped to customers, they undergo a series of quality control checks to ensure that they meet the necessary standards. This can include inspections for defects, fit testing, and performance testing.

Once the footwear has been inspected and approved, it is ready to be shipped to retailers or consumers. The footwear product distribution can involve various channels, including stores, online retailers, and wholesalers.

The footwear industry is a vital part of the global economy, with billions of dollars in sales each year. It is also a major employer, with thousands of people working in design, production, and distribution roles.

In recent years, there has been a growing focus on sustainability, and ethical practices in the footwear industry as consumers become more conscious of their purchasing decisions’ environmental and social impacts.

Footwear manufacturing is a complex and multifaceted process that involves a range of different skills and expertise. From the initial design phase to the final distribution of the finished product, it takes a wide range of people and resources to bring a pair of shoes or other footwear products to market.

If you start your shoe brand like Nike, and find a shoe factory to produce shoes for you. Then you have to understand the process of footwear manufacturing. I hope you know how shoes are made now.

Related other articles:

How Much Does It Cost To Start A Shoe Company?